中文

kayo@kayosmt.com

中文

kayo@kayosmt.com

Product Dimensions:

Product Feature:

1. Precision:

Dedicated Math Model with Repeatability ± 12.5 μm (± 0.0005 ") @ 6 σ, Cp ≥ 2.0.

2. Special adjustment platform:

Dedicated high-rigidity UVW module drive mechanism and inverted triangle Z-axis lift mechanism to effectively improve the stability of the platform tuning, micro-fine adjustment to achieve ultra-fine drive, make sure the machine meets the requirements of higher precision printing. Simple and reliable structure, convenient adjustment, quickly achieve automatic adjustment of the PIN pin lifting height of PCB boards with different thicknesses.

3. Programmable suspension self-adjusting stepper motor, drive and print head:

Independent direct-connected stepper motor control, built-in precision pressure control system, can accurately measure the blade original pressure value, without consider blade type, length, weight or thickness changes. Programmable realizes printing process flexible; Designed according to front and rear blade required different pressure & the stability of the lift to prevent solder paste leakage and the blade with a certain flexibility of the clamping design, blade pressure, lifting speed, printing speed, printing range are adjusted through software, and provide customers a variety of stripping module ways to adapt PCB with different tin requirements, providing a good printing control platform for customers.

4. PCB positioning system

Flat belt drive, effectively improve rail capacity, speed; stepper motor drive, programmable to achieve different transport speeds and movements; new concept rail guide, seamless transmission to ensure the reliability of PCB transport; adaptive PCB board thickness, easier process; Software can adjust pressure elastic lateral pressure, could equip with the overall chamber vacuum or multi-point part vacuum at the bottom.

5. Cleaning system

Automatic cleaning structure; high-power fan plus venturi vacuum device for vacuuming; dry, wet, vacuum three cleaning methods, can choose any combination freely, the user can set the cleaning cycle, time and speed parameters according to the actual needs; length and short wiping paper universal, easy disassembly, saving resources; soft wear-resistant rubber wipe board, thoroughly cleaned, easy to disassemble.

6. High adaptability steel mesh frame clamping system

Realize the printing of various meshes’ sizes (370mm x 470mm ~ 737mm x 737mm), and can realize the rapid replacement model in the production process; Y direction automatic positioning.

7. Electronic control system

Adopt self-developed modular integrated circuits, safe, easy maintenance; use the most advanced industrial control system, achieve to modify the parameters during operation.

8. Image and optical system

New optical system - uniform ring light and high-intensity coaxial light, equipped with the function of non-polar adjustment of brightness, making all types of Mark points can be very good identification (including rugged Mark points), adapt to tin, copper, gold-plated, HASL, FPC and other types of different colors’ PCB. Four light source adjustable, telecentric lens, illuminating the stencil and PCB board simultaneously up and down.

9. Easy and convenient graphical Chinese / English user interface

Using windows XP operating system, independent research and development of graphical man-machine interface: especially in the navigation effect of program file to facilitate all operators quickly familiar with the operation; Chinese / English switched menu, operation log, fault record / fault self-diagnosis / fault Analysis tips / light alarm and other functions, making the operation simple and convenient.

10. 2D solder paste printing quality inspection and SPC analysis

2D function quickly detects for offset, less tin, leaking, linked tin and other printing problems, detection points can be increased randomly; SPC software can analysis the machine CPK index according to the samples collected by machine to ensure printing quality.

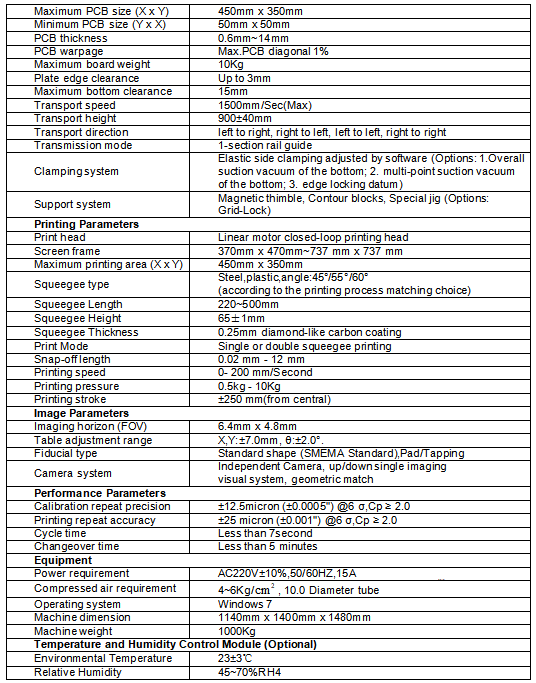

Product Specification: