中文

kayo@kayosmt.com

中文

kayo@kayosmt.com

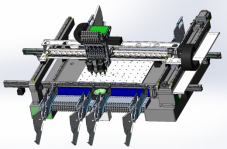

Product Display:

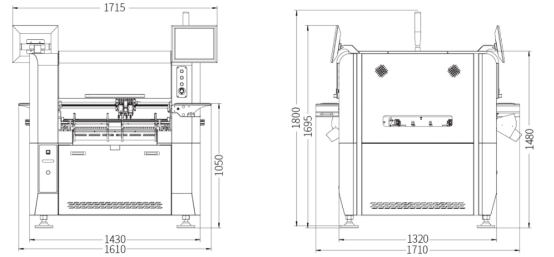

Product Dimensions:

Product Description:

1. A compact, comprehensive, non-discounted performance PNP machine.

2. Suitable for current and future SMT applications.

3. KAYO-S8 provides excellent performance and is a creative and truly highly flexible mounting method.

4. KAYO-S8 can provide equally excellent mounting speed, intelligent functions, and component flexibility.

5. KAYO-S8 is very suitable for medium & large batch production in a production environment of highly mixed products.

6. The comprehensive intelligence advantage of KAYO-S8 software shortens the machine program and feeder change time, which is conducive to small batch and multi variety production, and the comprehensive production capacity is unprecedented.

7. As a part of the entire KAYO mounting line solution, KAYO-S8 is extremely valuable. Existing KAYO users can seamlessly connect new and old machines to improve productivity and achieve unprecedented flexibility.

8. For new users of KAYO, KAYO-S8 provides very high component flexibility and refreshing mounting speed. Up to 18000 components per hour.

9. Intelligent software programming, automatically optimize the recognition path, and man-machine exchange to allocate component positions; supports multiple feeding methods such as tape reel winding, tray, tube, and bulk.

Product Feature:

lHuge feeding capacity: 78*8mm.

lIntelligent software achieves efficient and convenient PCB production under the best production conditions (component paths, nozzle self allocation).

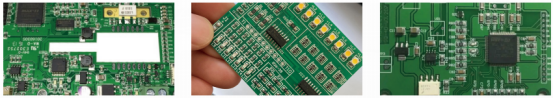

lComponent processing range: From microchip 0201 to Max.40mm components, can handle up to 15mm components.

lFull automatic springboard function.

lSelf-contained component library.

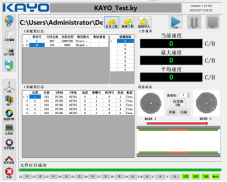

lFriendly image human-machine exchange interface.

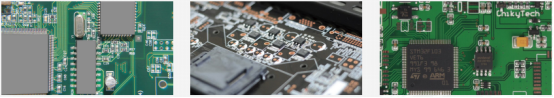

Product Details:

1. Marble worktable

The marble worktable with a thickness of up to 100mm ensures the mechanical installation flatness of the machine and its durability for long-term use.

2. Panasonic servo motor

The XY axis uses Panasonic servo motors to control the repeated positioning accuracy error within 0.01mm.

3. Intelligent human-machine interaction software

Supports multiple programming methods such as online programming, offline programming, and program import, with higher flexibility.

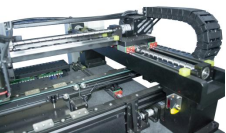

4. Non-stop flying vision + high pixel camera

Through the use of flying vision and high pixel cameras, high-precision mounting of conventional and micro precision components can be achieved without reducing production capacity.

5. Ball spline

The ball spline applied on the Z-axis improves the accuracy of mounting motion and rotation.

6. Grinding ball screw + linear rail guide

Adopt a structure of Taiwan TBI high-precision grinding ball screw and HIWIN heavy-duty linear rail guide, which has low noise and long service life, with small errors.

7. Feeder floating safety device

Two sets of laser sensors at front and rear, will immediately stop operation when feeder floats abnormally during high-speed production.

8. PCB clamping configuration

Waiting area, mounting area, and exit area - three section automatic input & output board;

Automatic width adjustment system based on PCB width;

Software controls transportation direction and provides more flexible production line configuration.

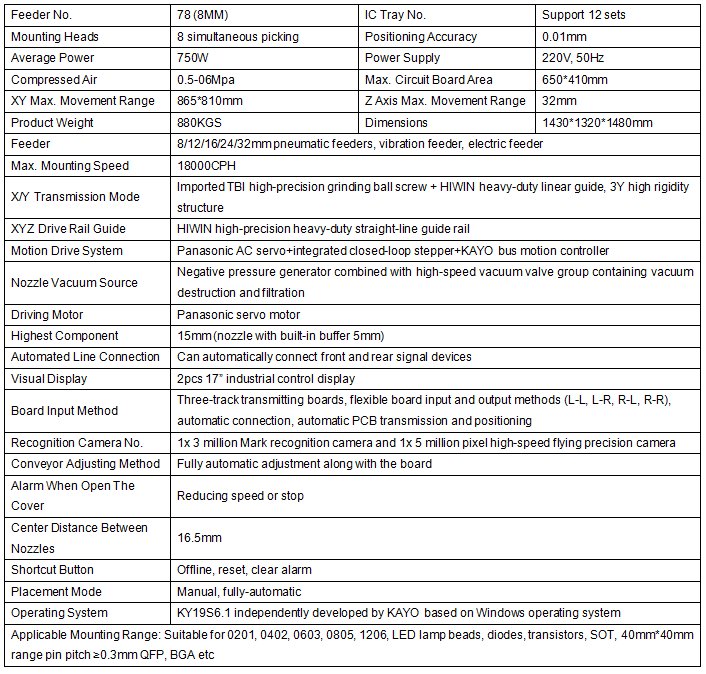

Product Specification:

Applicable Mounting Range:

Whole Production line:

Program 1:

Program 2:

Factory Overview: