中文

kayo@kayosmt.com

中文

kayo@kayosmt.com

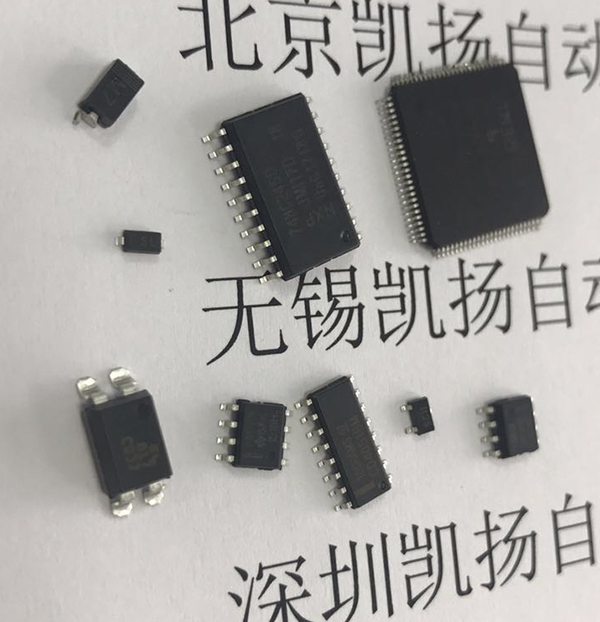

SMT on the basic requirements of the placement machine can be summarized in three words: one to stick accurate, two to stick well, three to stick fast.

First:mounting in the correct position, it contains the following two meanings

(1) components correct: the requirements of the assembly azimuth components type, type, nominal value and polarity and other characteristics of the mark to fit the product assembly diagram and list requirements, can not paste the wrong direction.

(2) Accurate azimuth: the end or lead of the components should be aligned and centered as far as possible in azimuth and Angle.Now in addition to the traditional PCB pad pattern, there are paste patterns based on practice printing.

Second:mounting very good, it contains the following three meanings

(1) Non-damaging components: components may be damaged due to errors in feeder, components, PCB and z-axis control during picking up and mounting, resulting in final mounting failure

(2) Suitable pressure (SMD height) : SMD pressure (height) should be appropriate, SMD pressure is too small, the welding end or pin of components float on the surface of the solder paste, the solder paste does not adhere to the components, in the transfer and reflow welding simple azimuth movement;Too much pressure on the patch, too much extrusion amount of solder paste, simple formation of solder paste adhesion, easy bonding during reflow welding: too much pressure may even damage the components

(3) To ensure the mounting rate: the failure of components during mounting can be caused by unreasonable parameter adjustment of the mounter, poor mounting performance of components and defective feeder and nozzle, which is called "falling" or "throwing".In practical production, use "mount rate" to measure, when mount rate is lower than the reservation level, must see the reason.

Third:mounting very fast.

Usually a circuit board has tens to thousands of components, which are attached one by one. The mounting speed is the basic requirement of production efficiency (capacity).The mounting speed mainly depends on the speed of the mounter, and is closely related to the optimization of mounting process, the use and handling of equipment.