中文

kayo@kayosmt.com

中文

kayo@kayosmt.com

Mounting is to remove SMC/SMD and other external mounting components from their packaging structure, and then paste them onto the designated solder pad location of PCB. In English, this process is called "Pick and Place".This is also some data called the patch for "pick and put" reason.Of course, the position of the solder pad should be coated with solder paste, or not coated with solder paste, but on the PCB surface covered by components has been coated with patch glue.After sticking, the components are initially stuck to the specified position of the solder pad by the adhesive force of solder paste or patch adhesive.

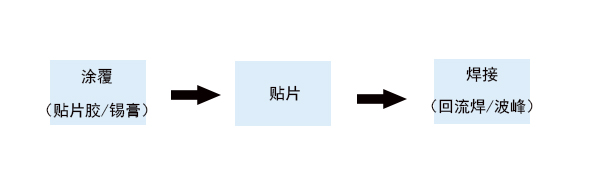

SMT basic process

In industrial production, the placement process is through a special placement machine,, also known as the "pick and place machine", is a special replacement of manual placement machine.The basic placement machine is composed of a frame, circuit board clamping organization, feeder paste chip head, nozzle and XY, z axis, during which the z axis can not only move in the z direction, but also can rotate in the θ direction.

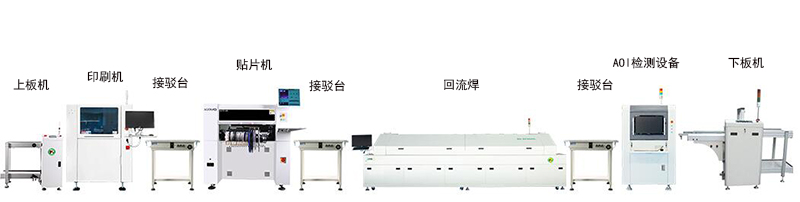

Typical reflow oven process production line

In industrial production,SMT process is realized by production line method.Production line, is the basic mode of modern large-scale production.The basic SMT production line consists of three typical processes and corresponding equipment: printing, P&P machine and reflow oven .

P&P machine is generally composed of high speed P&P machine and multi-function mounter. In one production line, only one printer and one reflow oven are needed.