中文

kayo@kayosmt.com

中文

kayo@kayosmt.com

Mount speed is one of the most basic characteristics of mount technology, and also the most sensitive, representative and easy to compare parameters in the performance index of mount equipment. In many cases, it is an important symbol of the grade and level of mount machine, and it is a decisive performance index in the evaluation, selection and use of mount machine.

Pasting speed refers to the ability of the pasting machine to mount components in unit time. It is generally expressed by the number of pasting components per hour or the pasting cycle of each component, such as 60000 points /h or 0.06s/ component.

Generally, in the parameters of the pasting machine, the pasting speed is only the theoretical speed, which is calculated according to the minimum feeding time of the nozzle, the shortest moving distance from the feeding position to the pasting position, the minimum pasting distance and other ideal states.Moreover, it is only the theoretical time of component mounting, excluding auxiliary time such as transmission time and preparation time

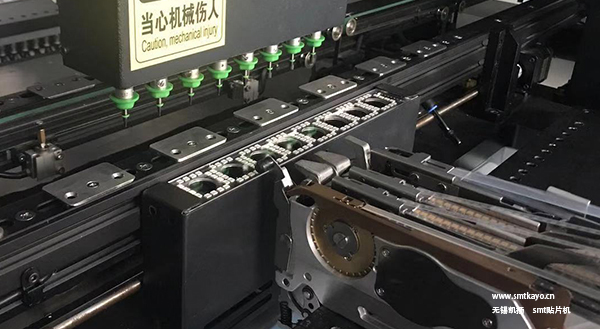

There is currently no accurate placement machine speed industry definition and measuring method, now patch mechanism manufacturer USES an ideal method of velocity measurement data, and do not include any additional factors, namely, regardless of PCB delivery and positioning time, the size of the PCB, components and type of mounting position and so on, only to a certain number of an element (for example, 120 chip components or 10 QFP packaged IC) according to the rules of the arranged loaded on the model, as shown in, and then calculate the average time for each component, how many pieces per hour or per piece of the number of how many seconds are given "mount speed".

Because of the electronic component and IC encapsulation SMT speed difference is very big, no matter what suppliers to speed, format and units are pasted on the theory, the speed is also known as nominal speed, relatively reference only, with every shift in the process of production can be pasted on the number of components (actual SMT productivity) is a far cry from

In addition, "cycle speed" or "test speed" is also used when comparing the mounting speed with different machines.It is the most basic measurement parameter of the SMT machine speed, similar to the above theoretical speed, but actually has not placed the parts, the machine is still in idle working mode.This velocity is faster than the equivalent theoretical velocity because it does not involve the influence of component pickup, centering and placement.Although the mechanical driving efficiency of the machine is compared, the cycle speed is a useful indicator, but it is of little practical significance to the user, so it is not generally provided in the parameters of the SMT machine.

Actual factors affecting the speed of mounting

Obviously, in the actual mounting production, it is impossible to only have one kind of component, and it is impossible to only arrange into a regular array. In fact, there are many factors that need additional time and affect the mounting speed.In actual patch production, the time to consider is described below.

(1) circuit board transmission and positioning time: the pasting completed circuit board from the table to the lower machine or waiting position and waiting circuit board from the upper machine or waiting position to the machine table.Common delivery practices require 2.5~5s, and some special devices can reach 1.4s.

(2) PCB datum correction time: due to the transmission of the PCB, PCB warping and mounting accuracy requirements, etc., with the PCB datum positioning is the best way.In general, one reference point can only correct circuit board deviation in XY direction: two reference points can correct circuit board deviation in X and Y direction and Angle deviation;Three datum points are available to correct board bias and Angle bias in the X and Y directions, as well as warping deformation caused by two panels after one side has been reattached to the backflow.

(3) nozzle replacement time: because there are various components in the printed circuit board, the need for different nozzle, attach the head of the nozzle often can not absorb all types of components, so, the general platform machine design nozzle automatic replacement function.

(4) component feeding and absorption time: general components in the absorption should be in place before feeding, but in the same material station continuous absorption, if the next material feeding time is longer than the time to replace another material axis to suck the material, the head needs to wait for the component feeding time.The suction time of the element includes the time required for the nozzle to move over the element, the nozzle to reach the suction position of the element driven by the z-axis, the vacuum opening of the nozzle, and the time required for the nozzle to return to the moving height with the element driven by the z-axis.

(5) table movement time: for turret machine, is the X, Y table to drive the printed circuit board from one position on the time: for the platform machine, is refers to the cantilever X, Y drive shaft to drive the mounting head from the previous position to the current position to be installed.

6 component recognition time: refers to when the component through the component recognition camera, the camera to take the component image time.For turret machines, since the turret rotates at a certain frequency, and the time taken by a single element is less than the time taken by the element for material collection and assembly, the recognition time of the machine element on the turret can be basically ignored.

Time: 7 components pasted on the suction nozzle to stick with the component fabrication plate above, suction nozzle through the Z axis drive down to patch level and into contact with the solder paste on the bonding pad, vacuum suction nozzle closure and leave the height of the patch, suction nozzle blow open in order to keep the parts with the leave of suction nozzle belt, suction nozzle the sum of the time required to return to the original height

8) sets the head alternately waiting time.

In short, the actual pasting speed of the pasting machine is much lower than the theoretical speed indicated.Depending on the number, distribution, type and number of the SMT components on the circuit board, as well as the characteristics and forms of the SMT machine, the actual mounting speed of the SMT machine is usually only 60%~85% of the theoretical speed.

reference

1 wu yiping, xianfei electronic assembly technology wuhan: huazhong university of science and technology press,2008

2. Wang tianxi, wang yuming SMT technology and equipment Beijing: electronic industry press,2008