中文

kayo@kayosmt.com

中文

kayo@kayosmt.com

Product Description:

1. Body linear design, use spray technology, nice and durable.

2. Three independent 1.6m preheating area, full hot air preheating, with spotlight compensation device, make PCB boards to get good welding effect.

3. Patented die-casting type titanium alloy chain claws, non-stick tin, never deformation, long life.

4. The whole processing observation window, easy to operate and maintain.

5. Tin oven up/down and in/out, automatic and manual adjustment combined. With backrest design to prevent misuse damage to the machine.

6. Equipped with cooling module, temperature compensation module, suitable for lead-free soldering and a variety of process requirements.

7. Latest invented ultra-smooth, ultra-high filter, significantly weaken the tin flow shocking and turbulence generating in the flow channel, stable tin wave, significantly reduced oxidation, easy maintenance.

8. Transmission mechanism adopts precise modular design, transmission accuracy, long life, easy maintenance.

9. Rosin spray device can be pulled out and removable, easy to clean and maintain.

10. Isolated spray device, fluxer smoke discharged from the dedicated air duct.

11. Strong parameter library function, all kinds of PCB process parameters can transfer and operate on-demand.

12. Adopt professional industrial computer control system to ensure the system’s reliability and stability.

13. According to the user set the date, time and temperature control parameters for automatic switching machine.

14. System fault self-diagnosis, fault reasons automatically display, troubleshooting methods can query at any time.

15. Heating temperature uses PID closed-loop control, temperature control stable and reliable.

16. Closed-loop automatic tracking spray system, spray width and time automatically adjusted, can set advanced and extended spray time on demand.

17. Automatically generate wave when passing boards, reducing the amount of tin oxidation to the maximum.

18. Transport system uses clutch limited power + current limiter dual protection.

19. Short circuit and overcurrent protection system.

20. Transport system closed-loop control. Stepless speed regulation, precisely control PCB preheating and welding time.

21. Industrial computer control system dual-wave soldering device, in addition to be compatible consistent machine’s automation performance, it also adopts streamlined body design, simple and convenient computer window system, make the automated production and management records to a higher level.

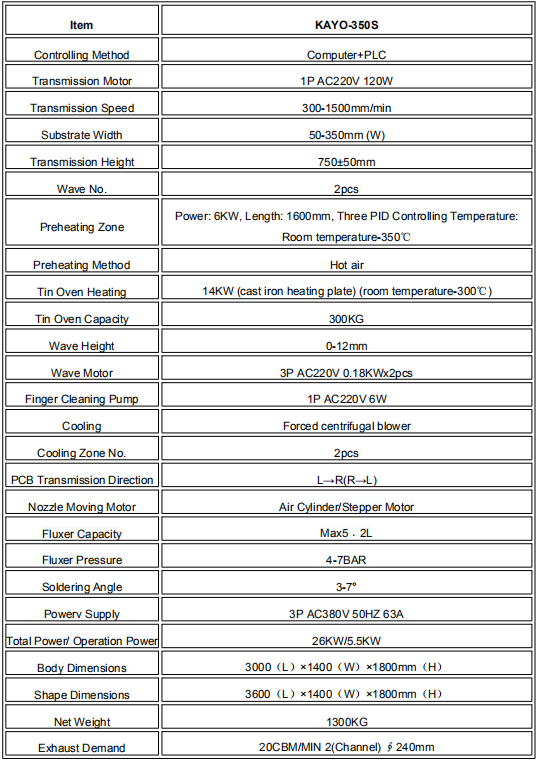

Product Specification: